Introduction

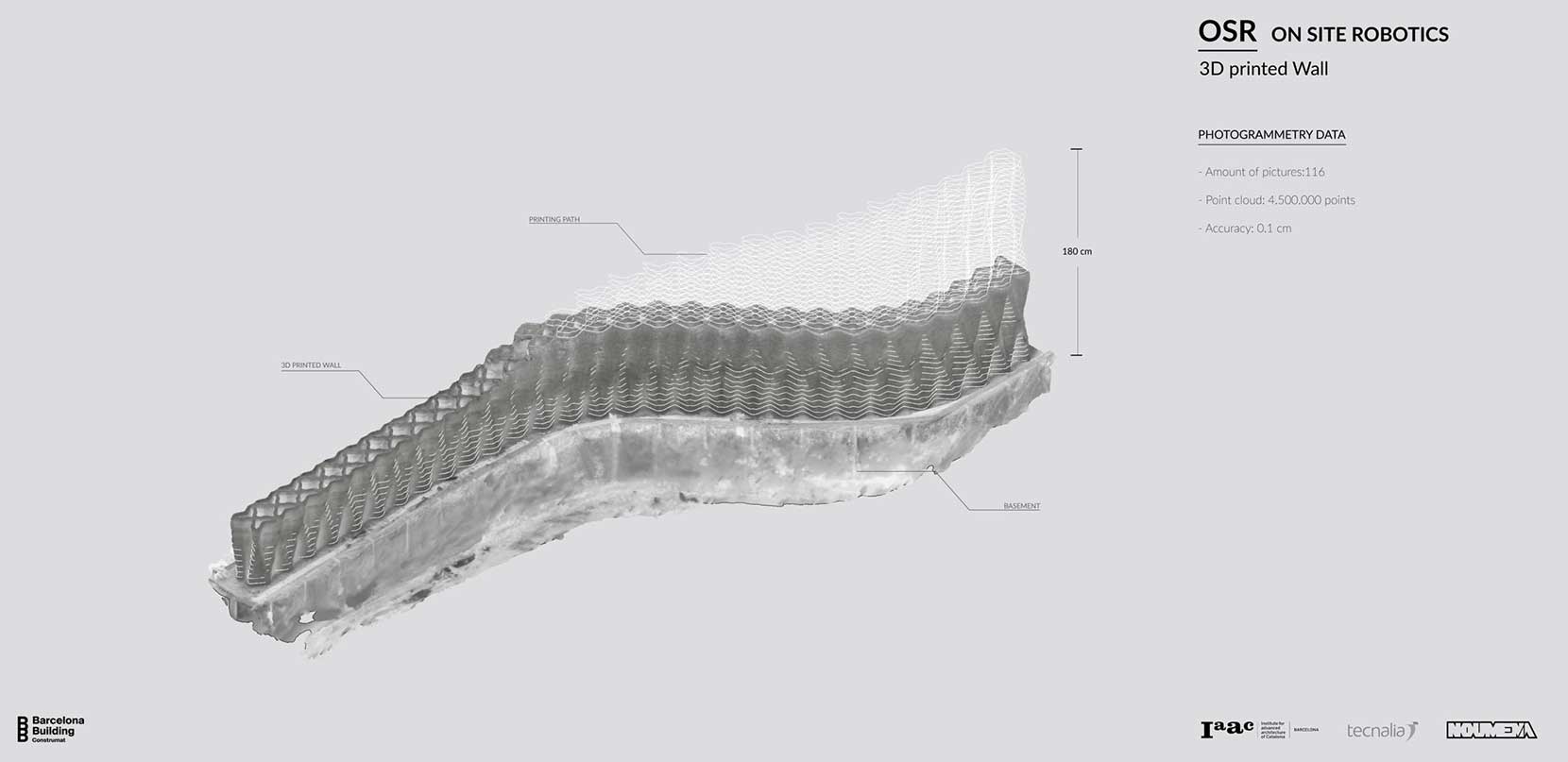

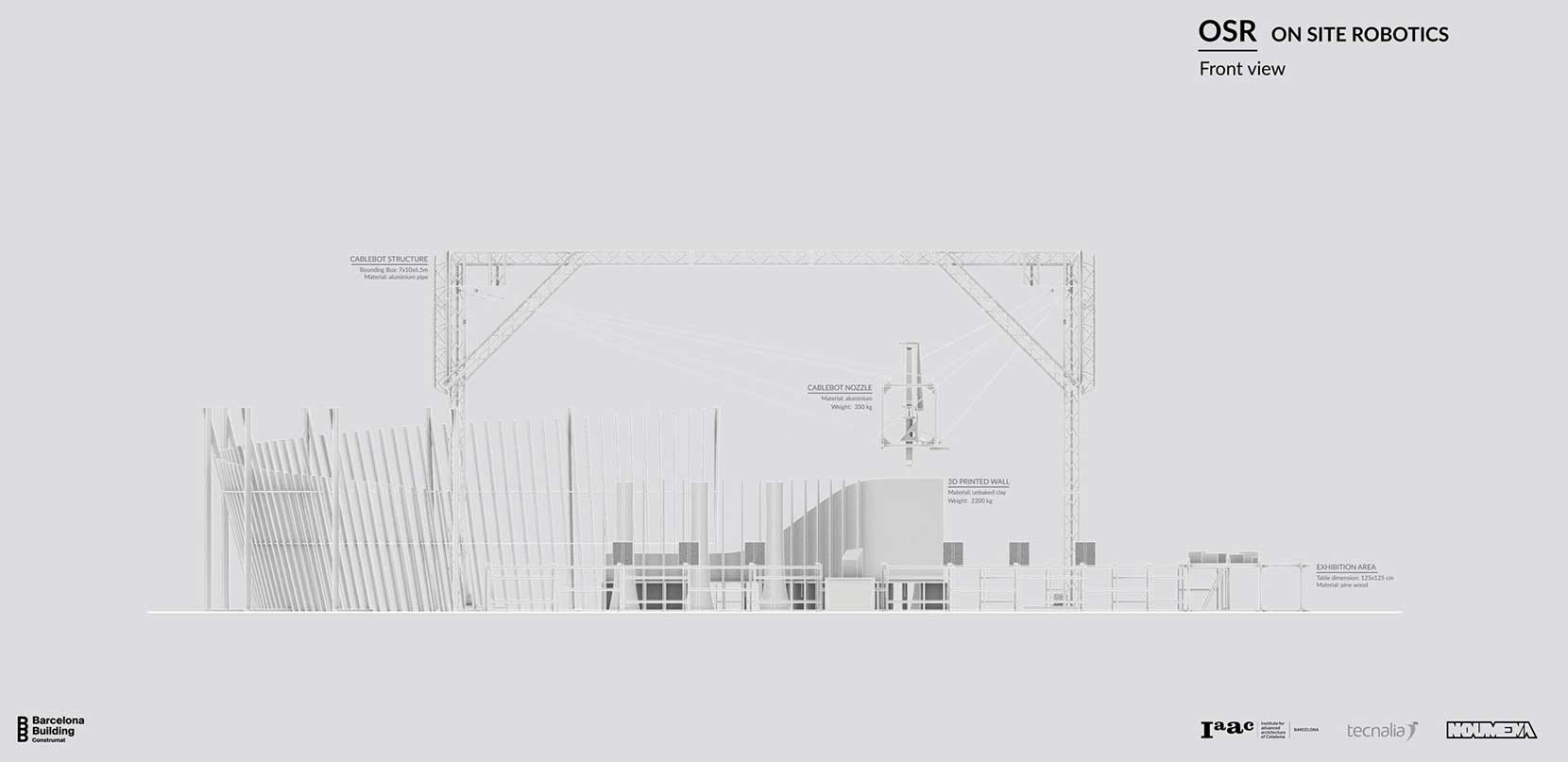

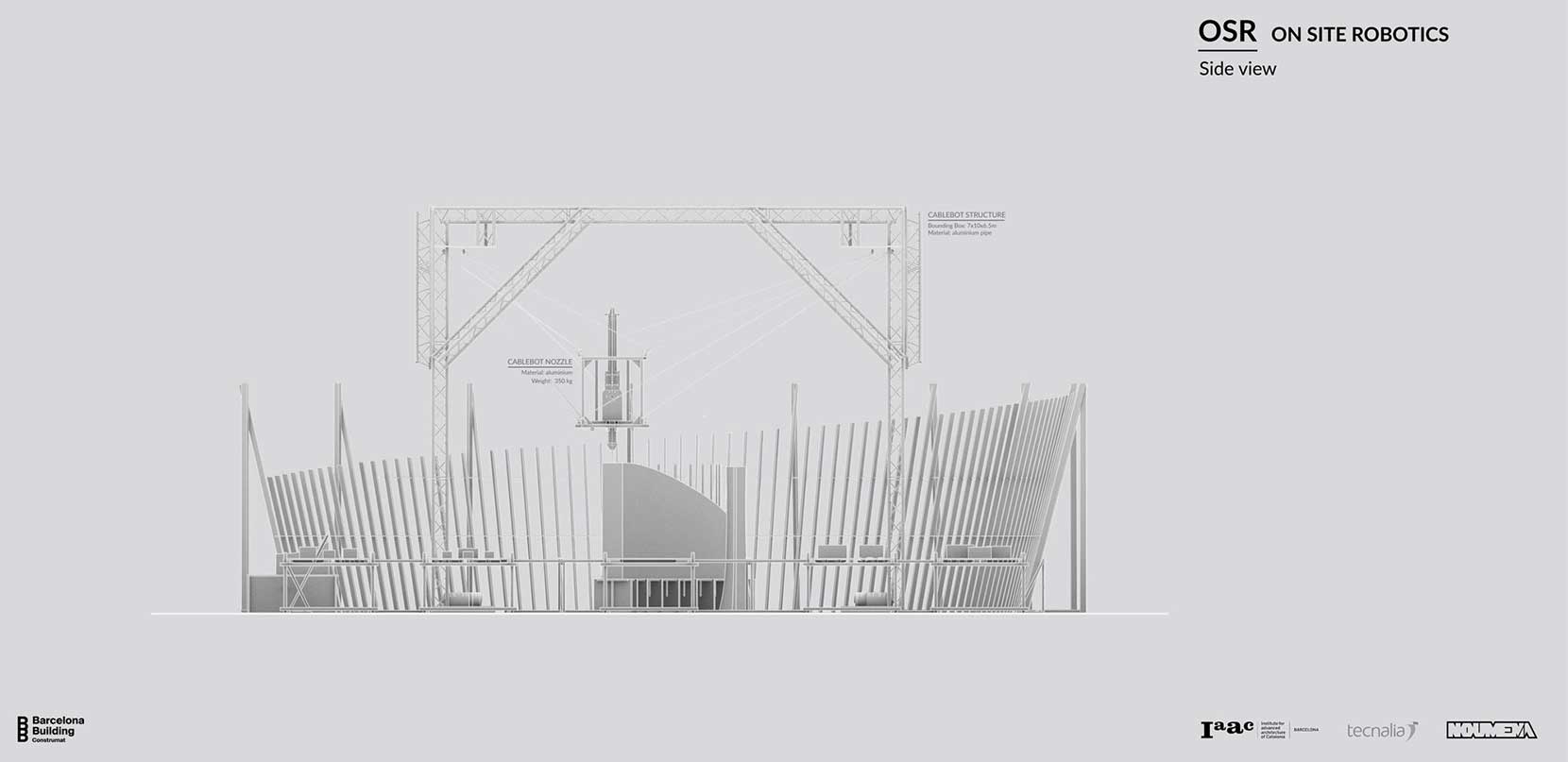

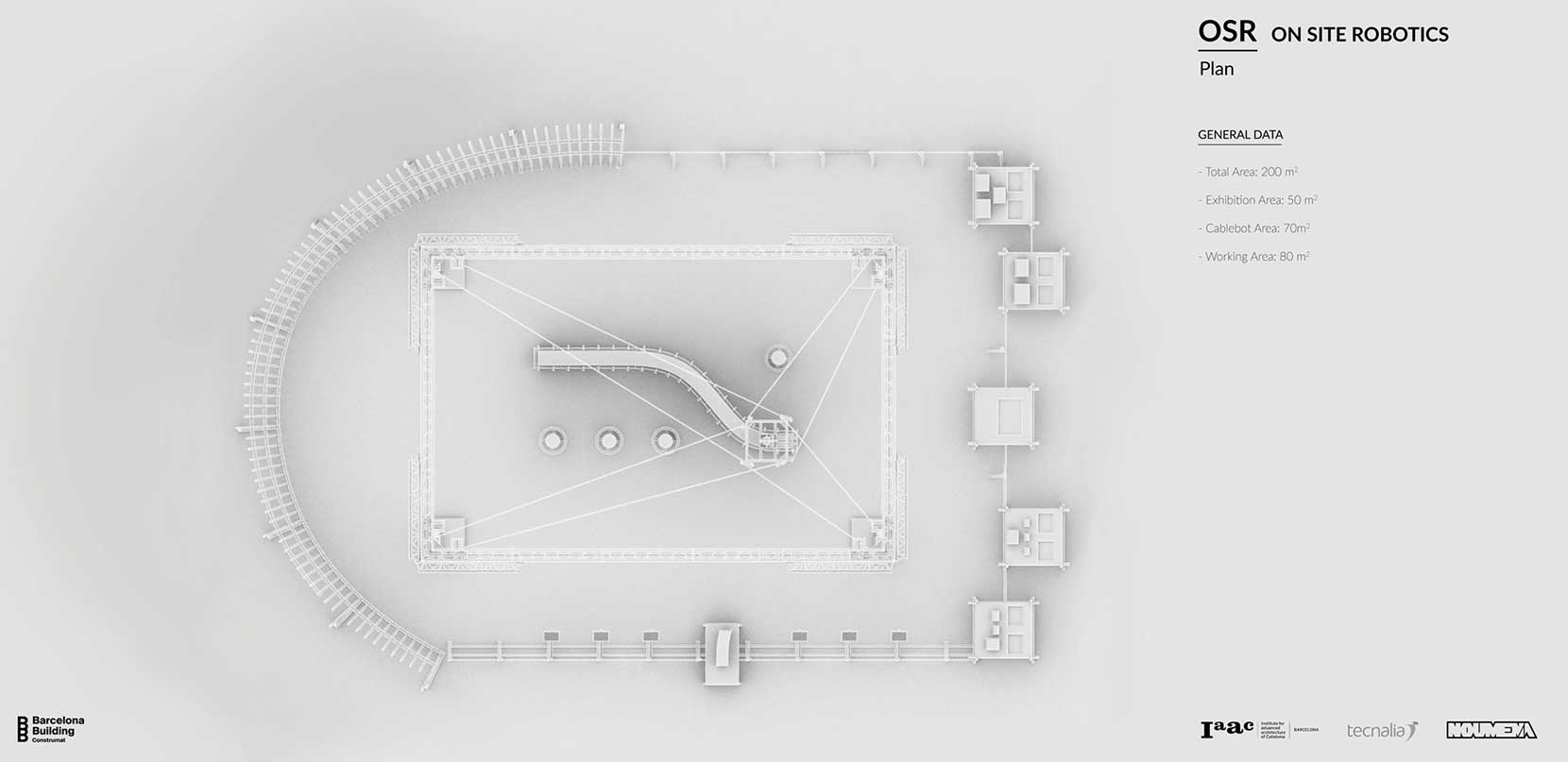

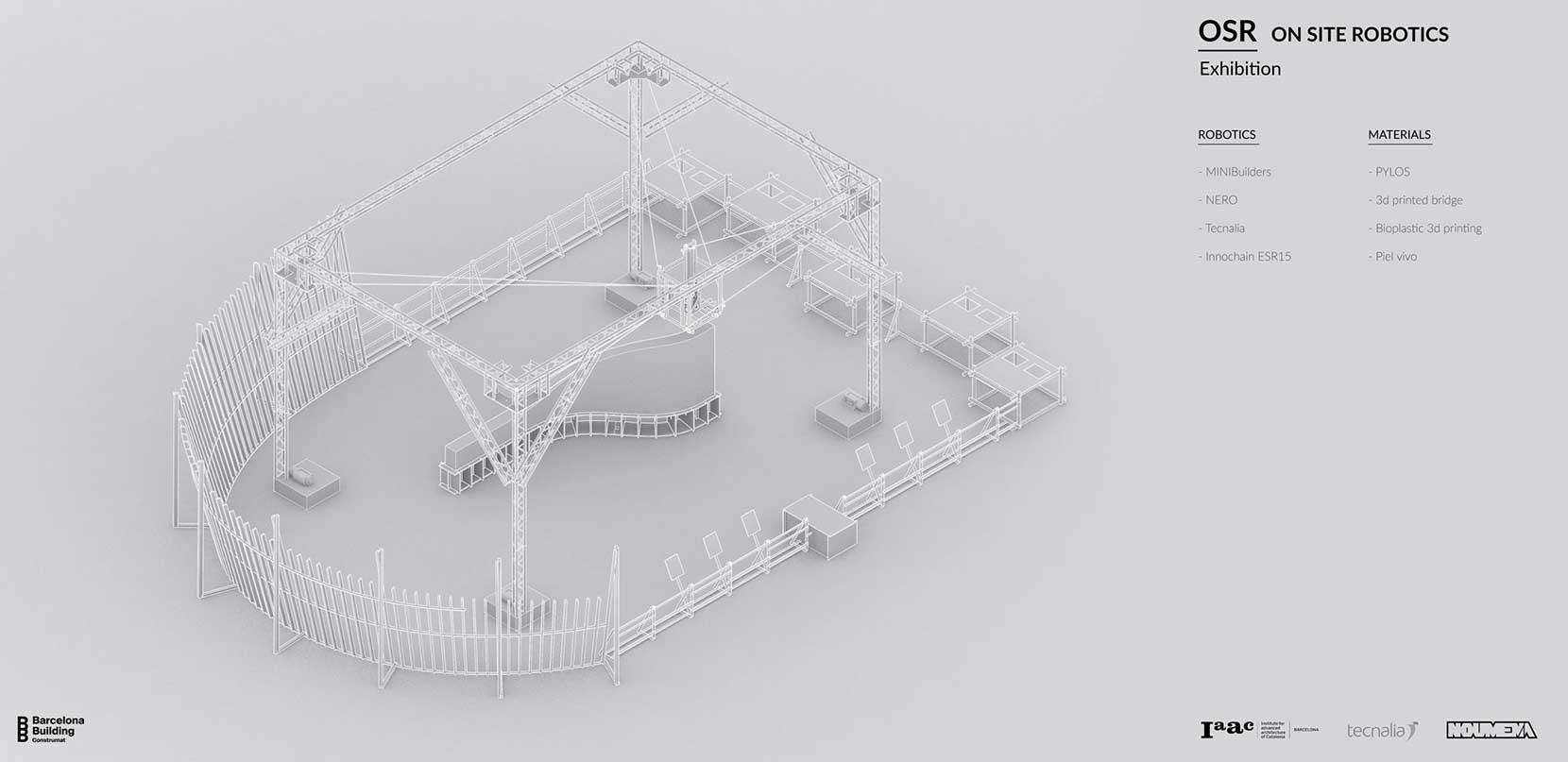

Combining technological advances in robotics (cable robot and drones), natural materials and CAD/CAM software, the aim of the project is to bring automation to the construction site, as well as allowing the production of high-performance buildings and their monitoring in real-time during the construction.

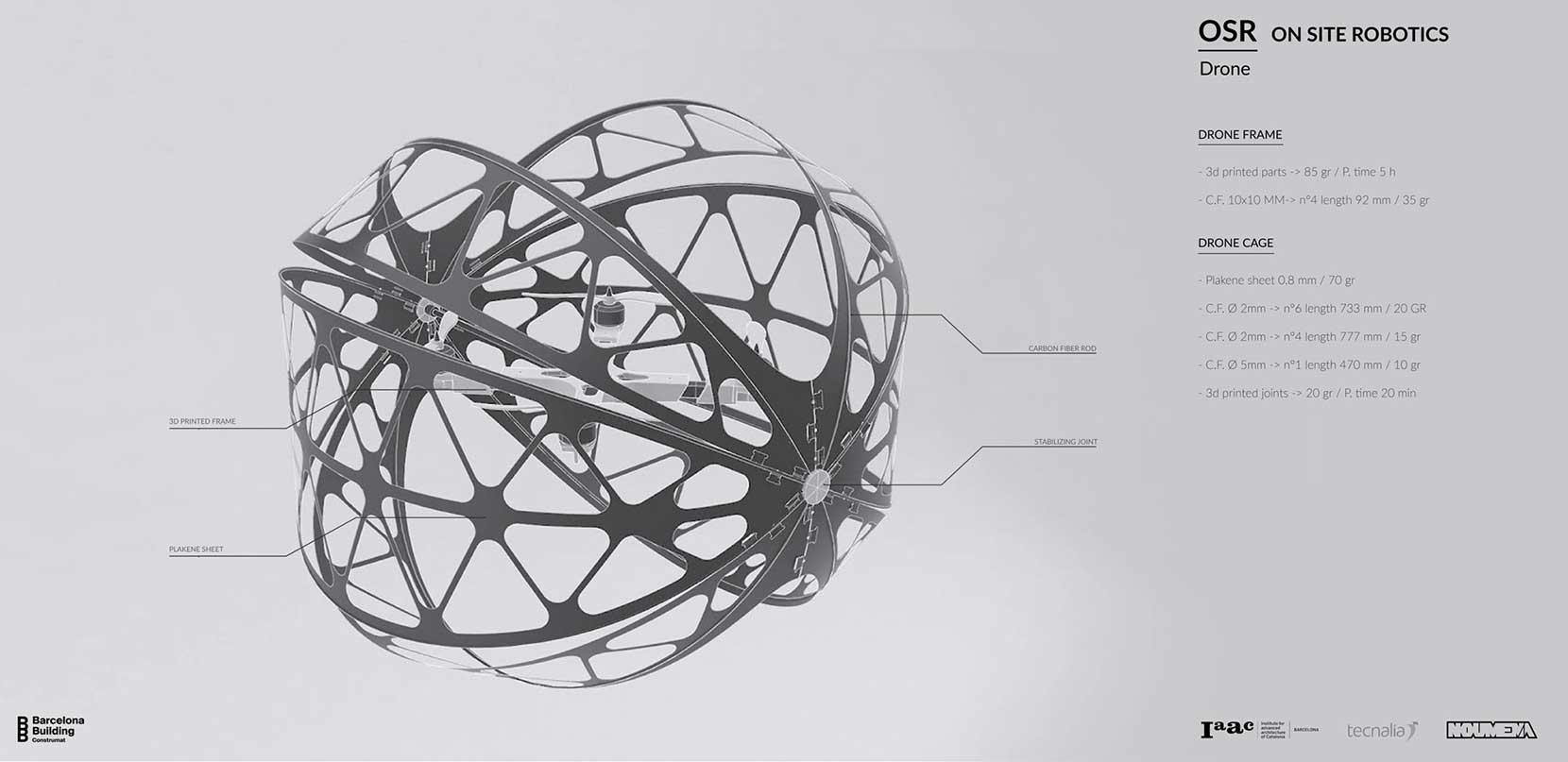

Drones

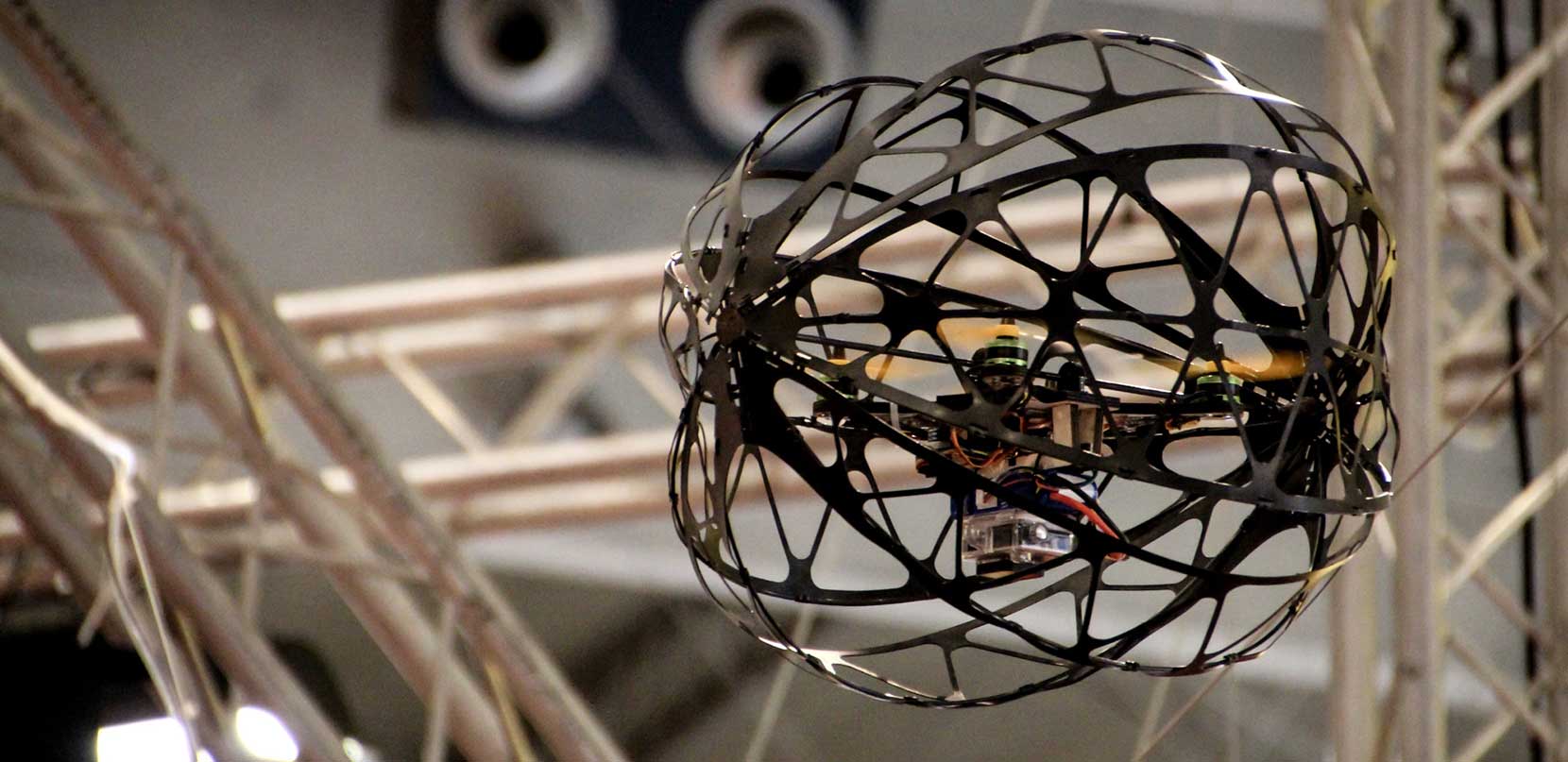

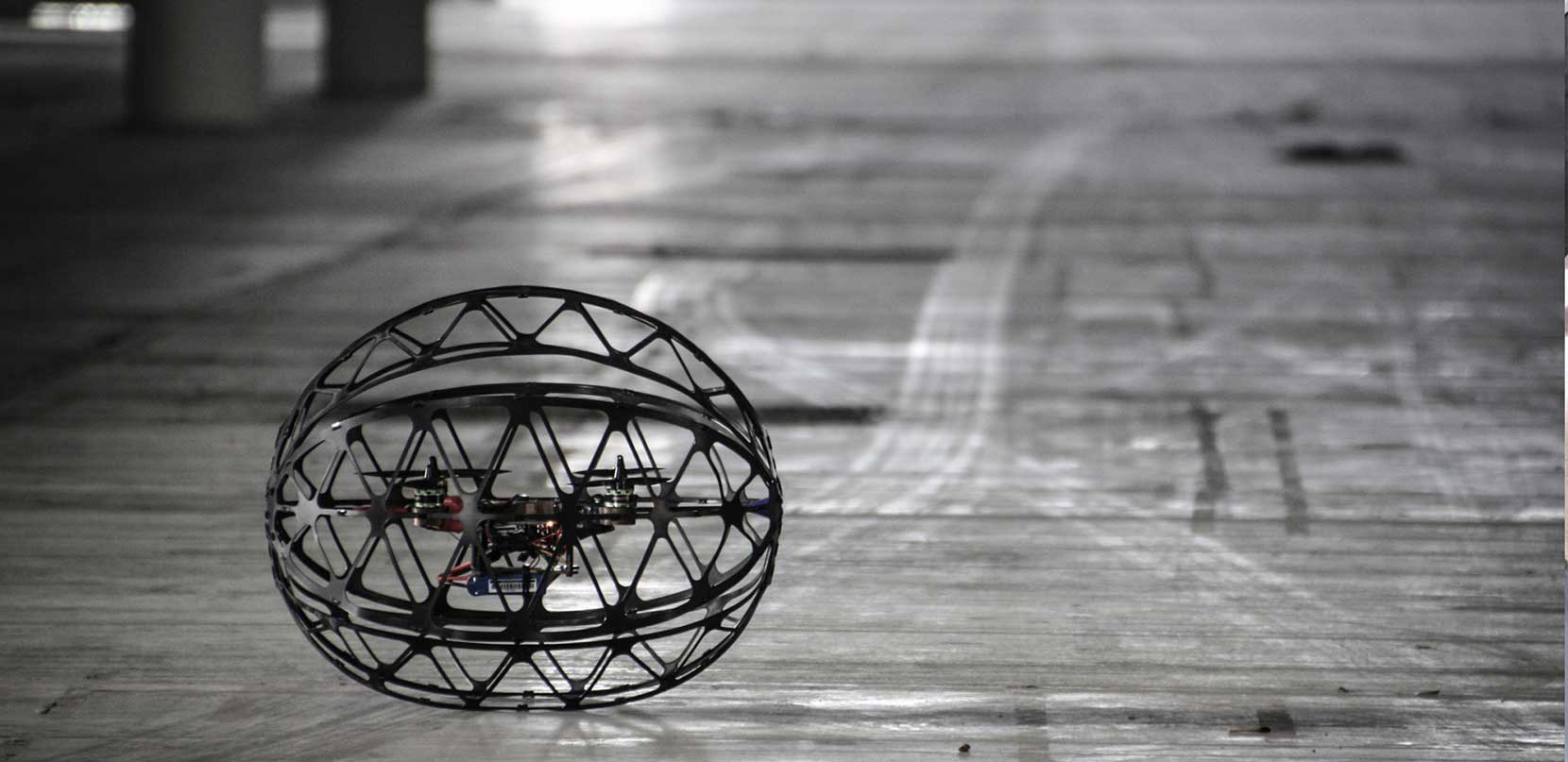

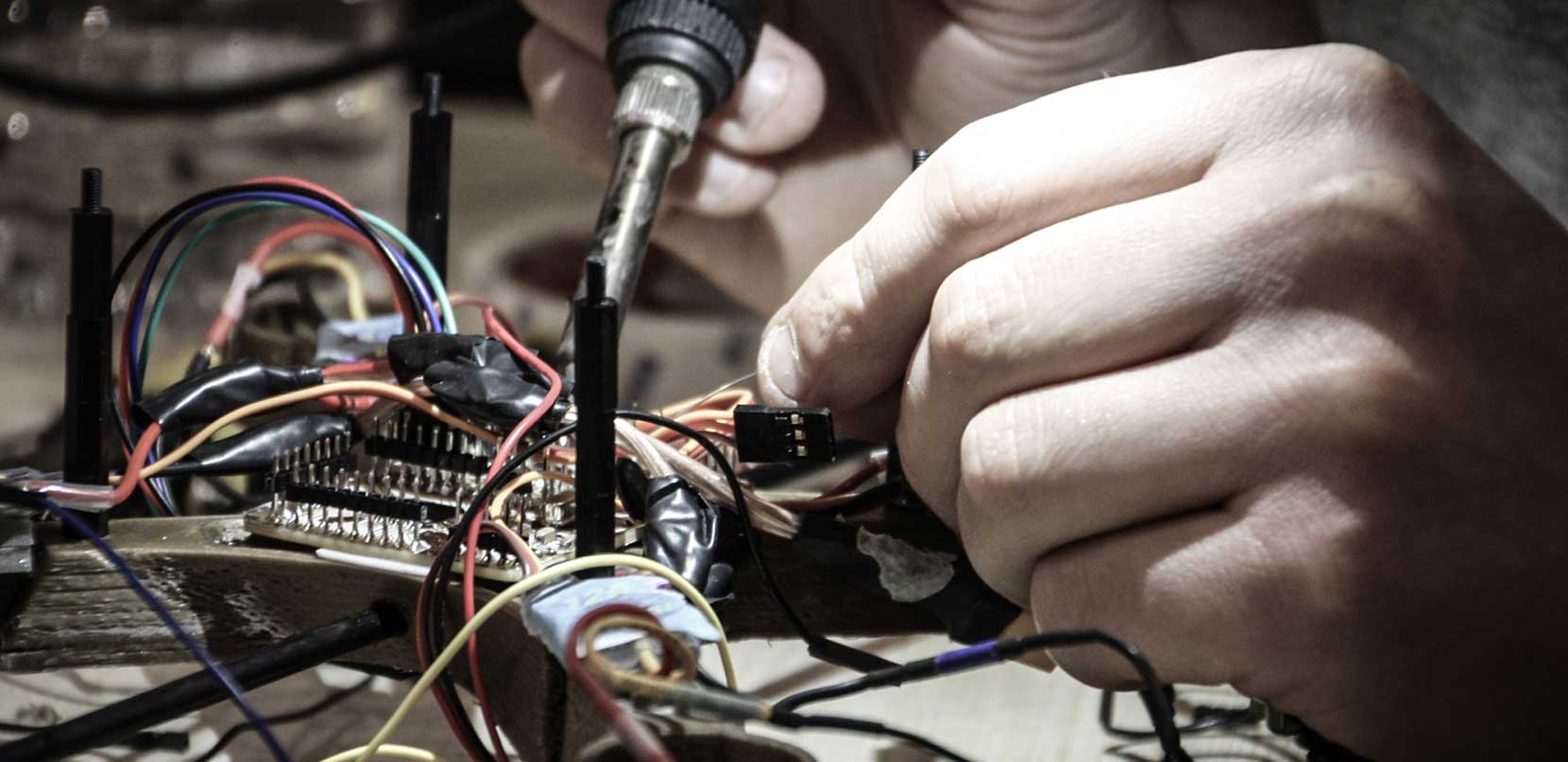

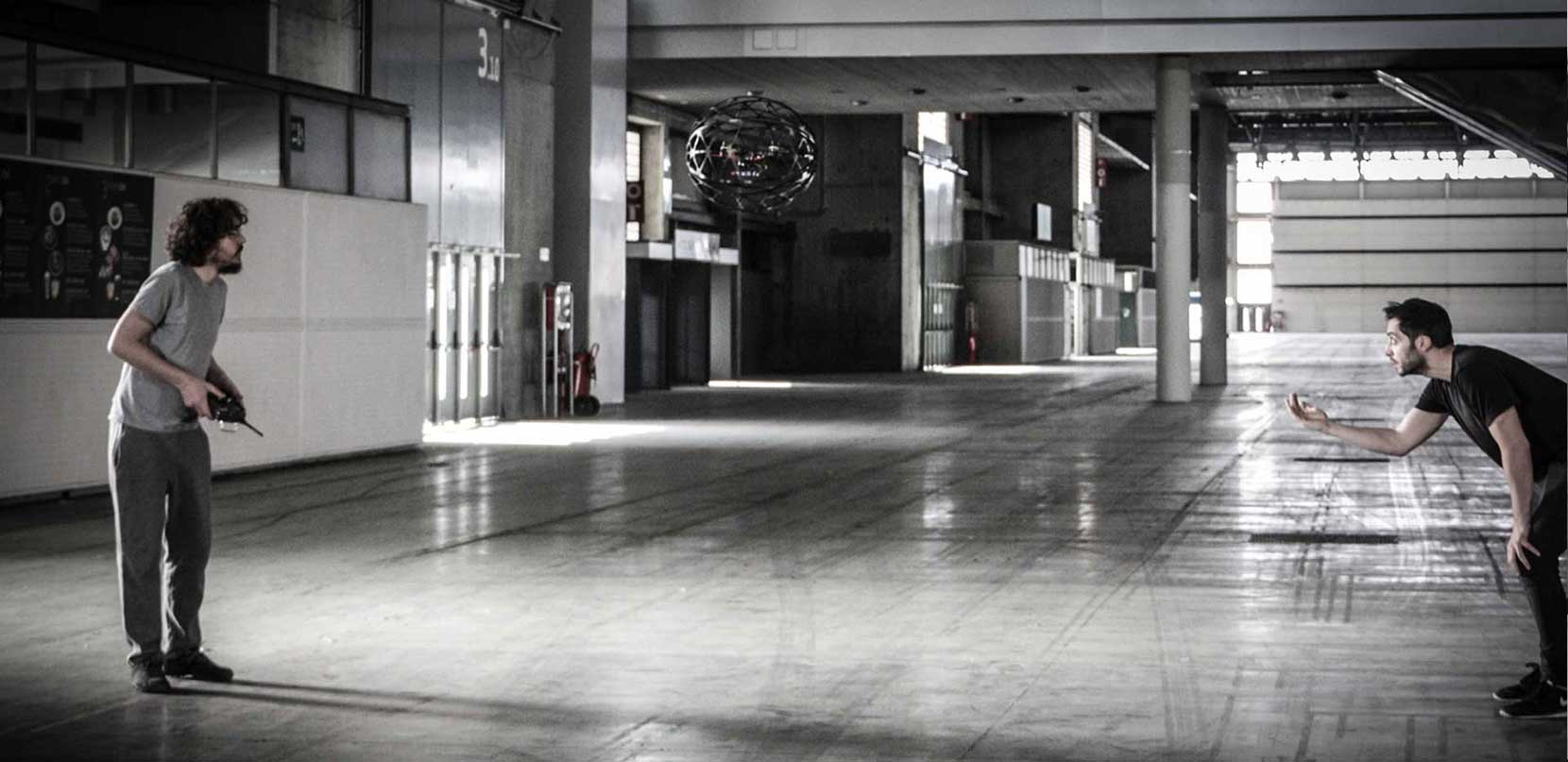

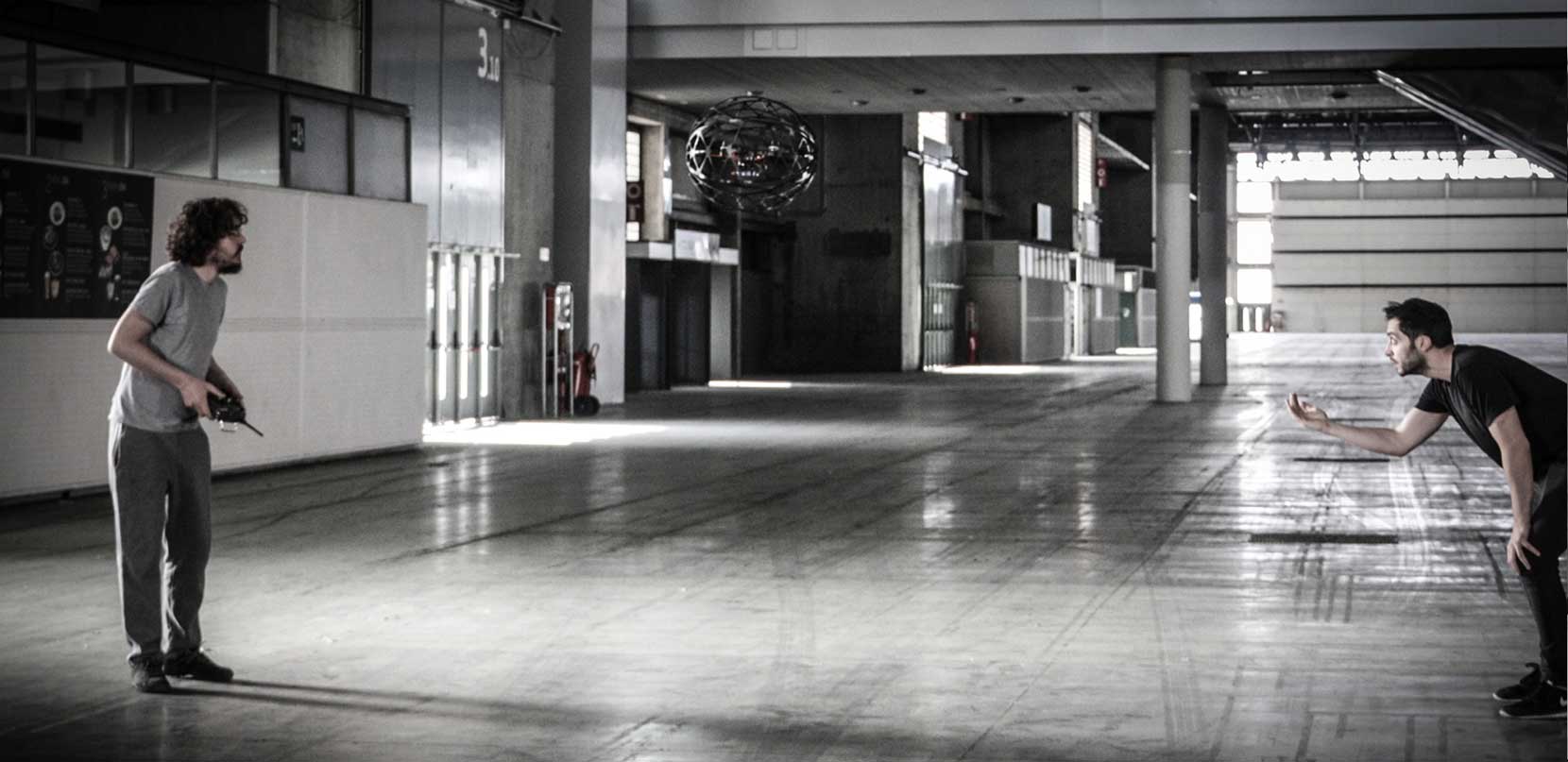

NERO / OSR

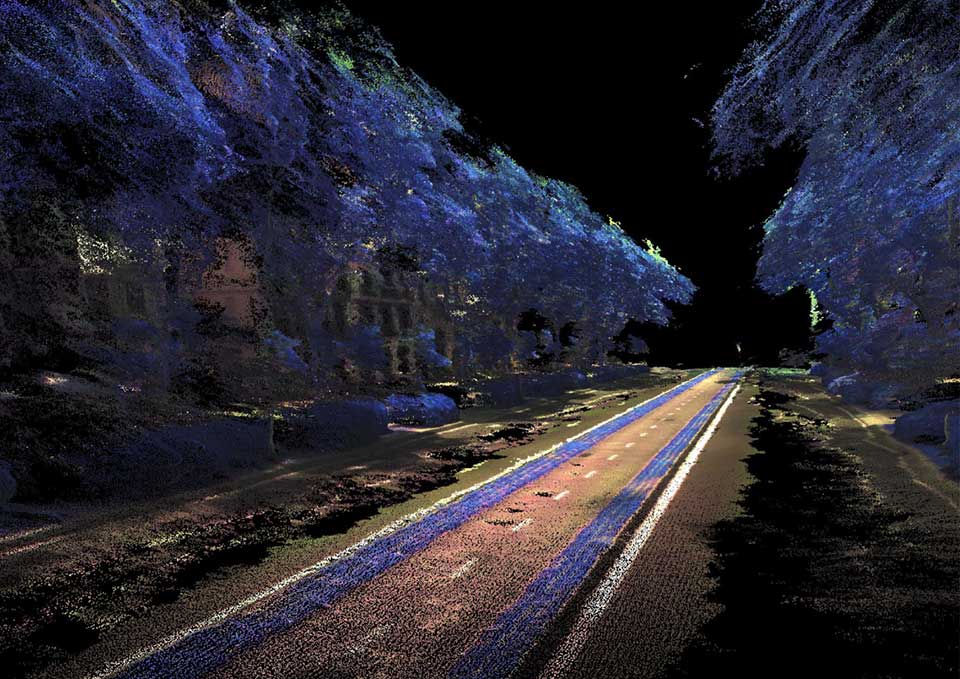

Noumena presents N.E.RO [Networking Environmental Robotics], a project exploring robotic applications in real case scenarios from construction sites to mapping public spaces and precision agriculture. Nero drones are customly designed to support the fabrication process through data-collection and mapping, providing services of 3d scanning and photogrammetry implementing on-flight sensors, thermal and infrared cameras. For OSR Nero is specifically monitoring the thermal conditions of the 3d printed wall, informing the fabrication process on the solidification status of the extruded material.

Exhibits

NATURAL MATERIALS

Pylos – Iaac

3D printed bridge – Iaac + Acciona

Bioplatic 3d printing – Iaac

Piel Vivo – Iaac

ROBOTS

Minibuilders – Iaac

Nero – Noumena

TerraPerforma- Iaac + Tecnalia

Innochain ESR15

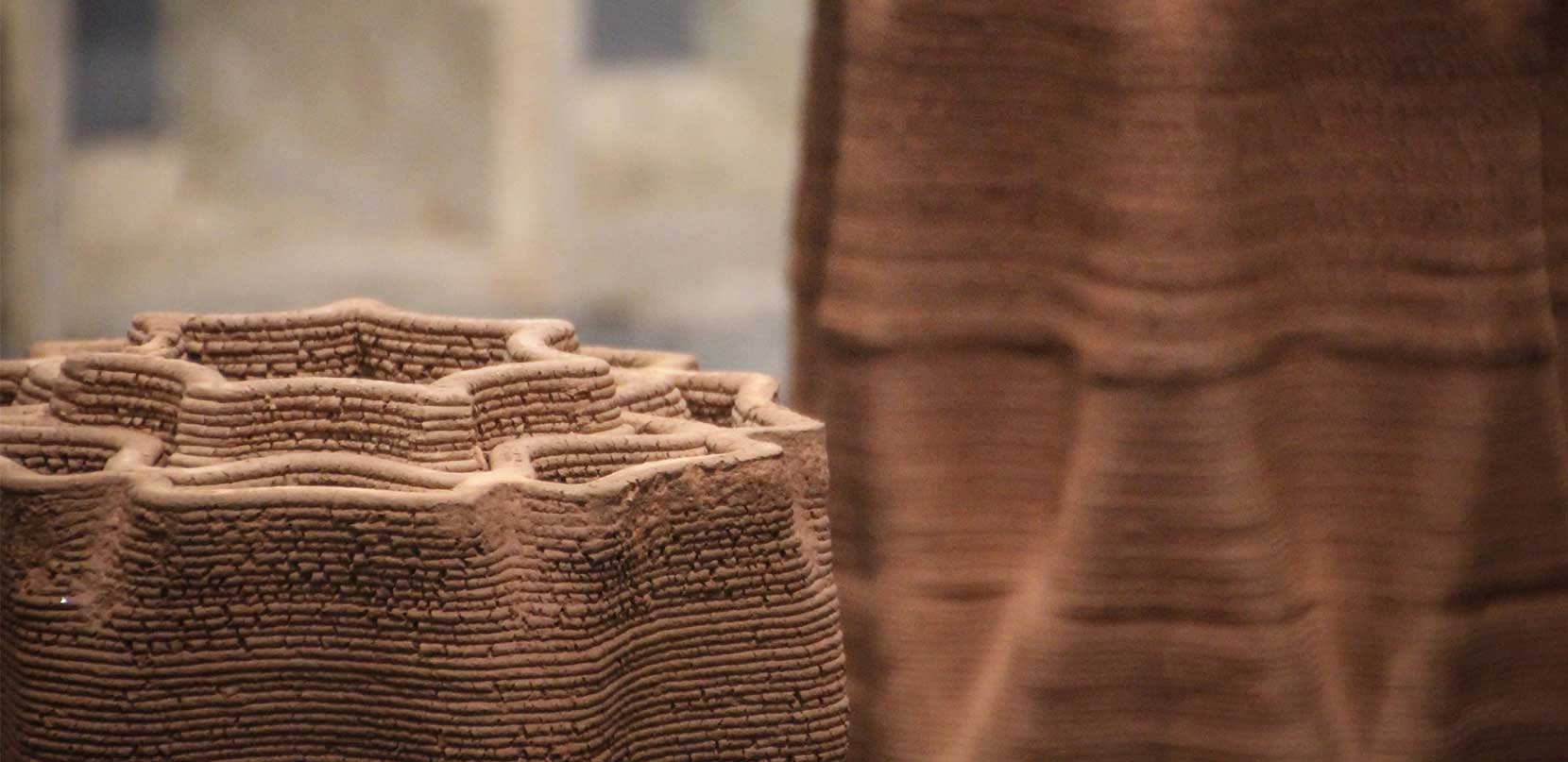

PYLOS

The objective was to develop a technique that went beyond the robot – relying only on its mechanical properties – and allowing a design research based exclusively on the material properties and behaviour. This research process included the optimisation of material mix, using only natural additives, as well as optimizing fabrication times.

3D PRINTED BRIDGE

The first pedestrian bridge printed in 3D in the world was inaugurated last December 14 in the urban park of Castilla-La Mancha in Alcobendas, Madrid. The Institute of Advanced Architecture of Catalonia (IAAC) was in charge of the architectural design of the bridge, which has a total length of 12 meters and a width of 1.75 meters and is printed in micro-reinforced concrete.

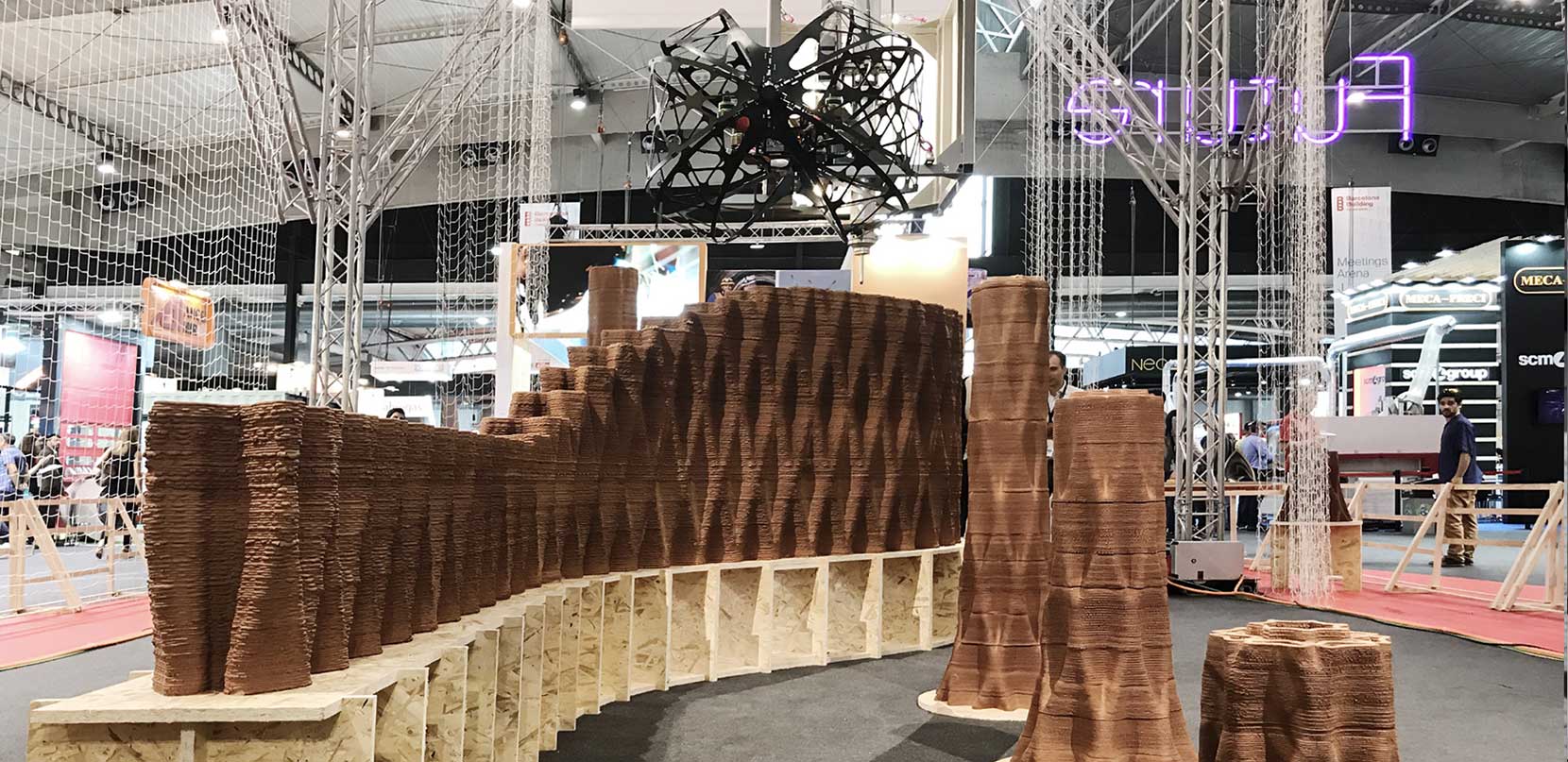

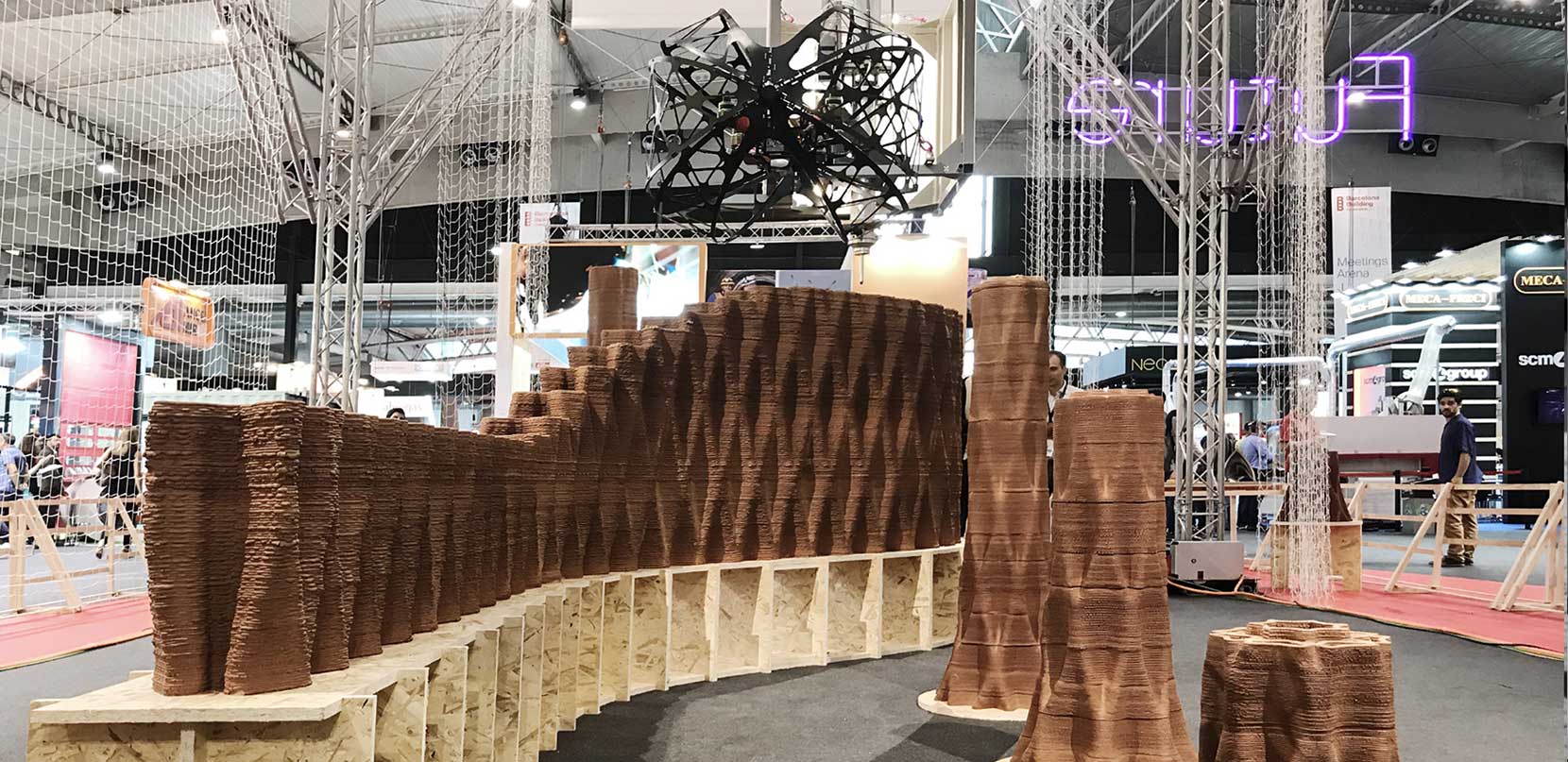

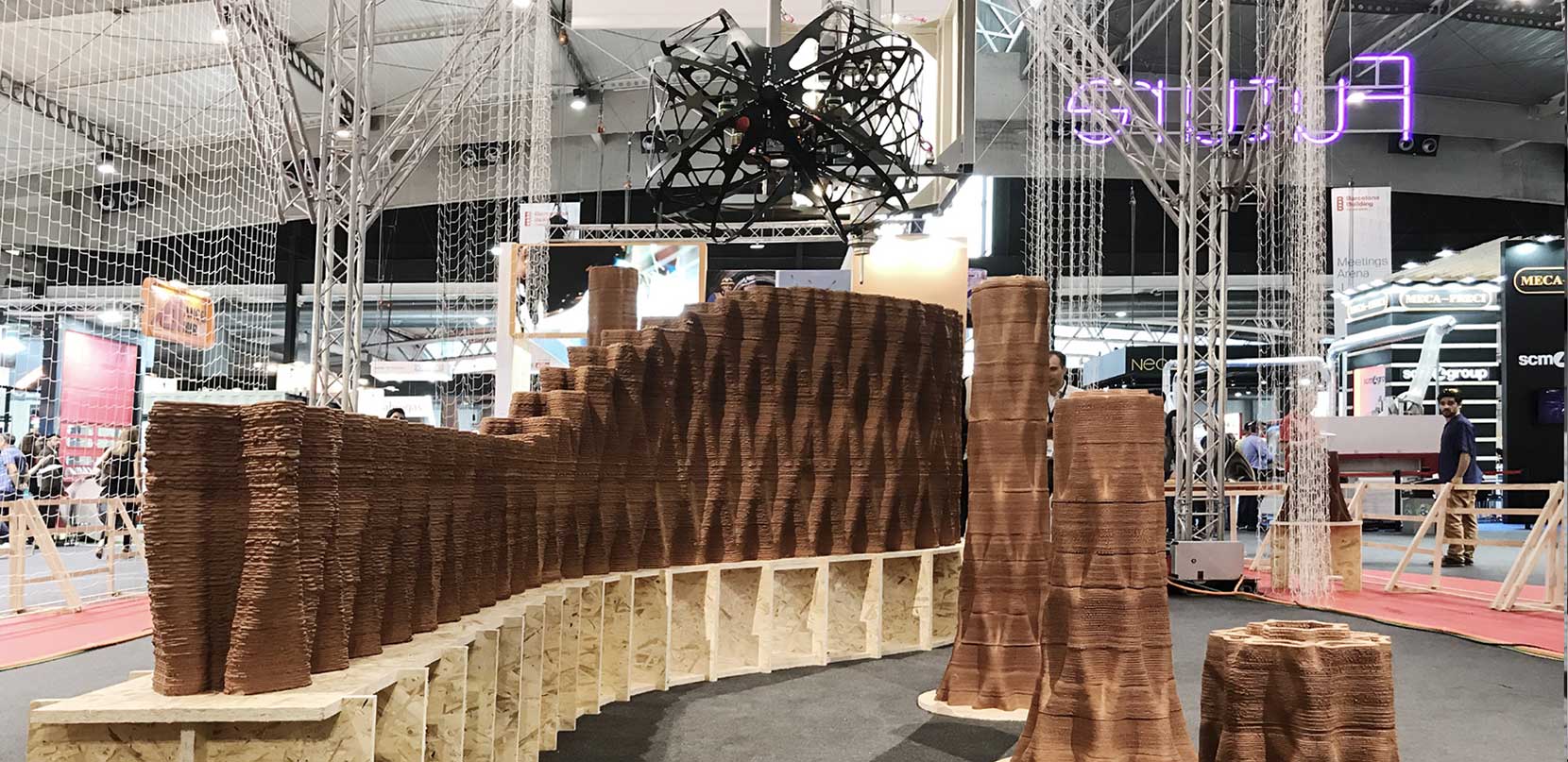

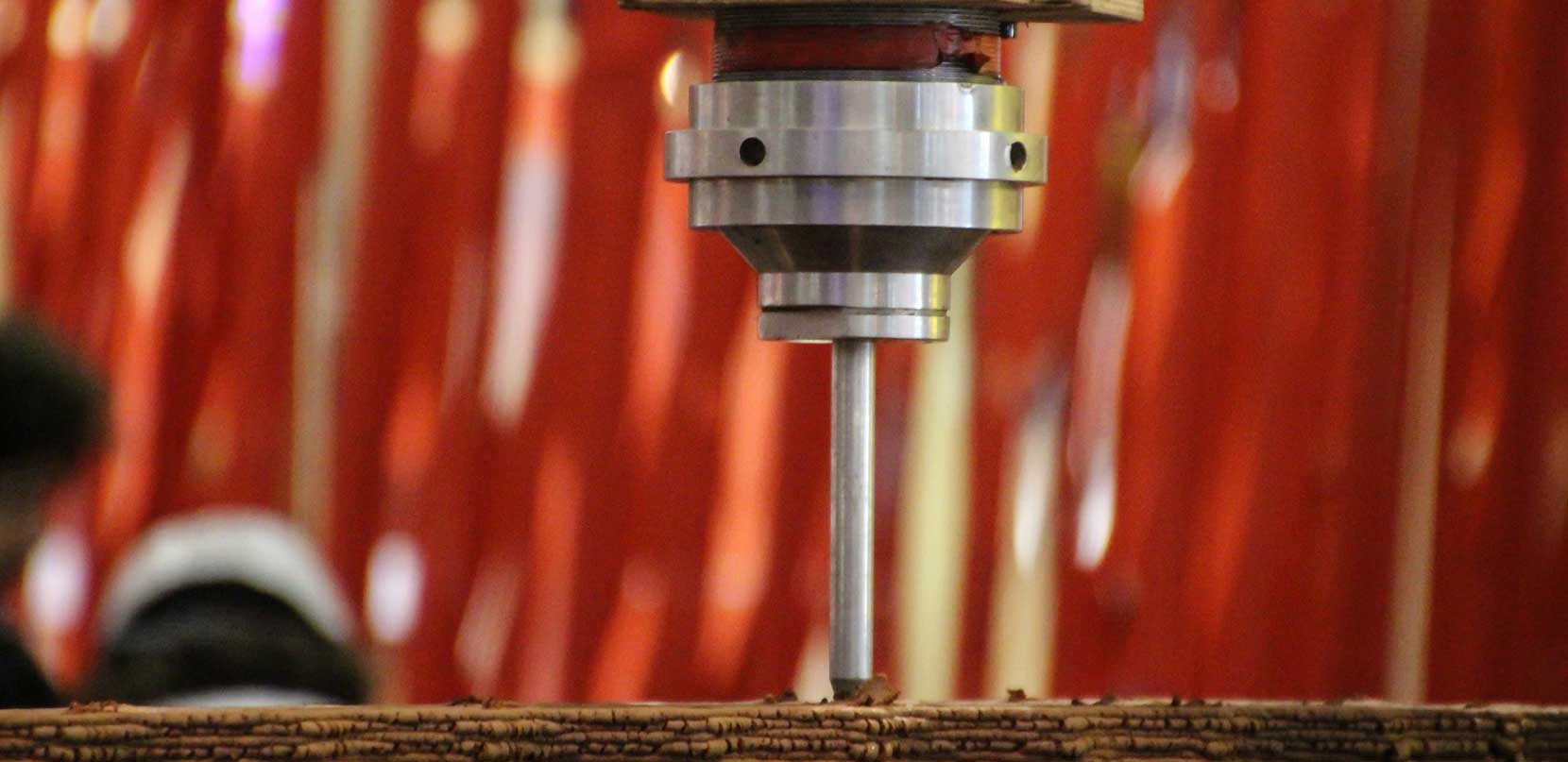

TERRAPERFORMA

The project TerraPerforma focuses on large scale 3D printing, the influence of additive manufacturing on building with a traditional material – unfired clay – and climatic performative design

BIOPLASTIC

Unlike plastics derived from fossil fuels, bio-plastic is made from organic compounds, and therefore can be part of the full life-cycle design, also known as the “Cradle-to-cradle” approach.

MINIBUILDERS

Robotics offers great potential towards innovation within the construction industry. However, in their current implementation applied to the architectural field, in particular construction robotics, these systems all share a specific limitation: the scale. Hence, the project here below elaborated aims to address this particular limitation through the creation of a technology that is both scalable and capable of fabricating structures using tools that are independent of the final product’s shape or size.

Credits

Year → 2017 / Location → Fira Barcelona, Spain / Organizers IAAC, Tecnalia, Noumena / Exhibition dates23th-26th May 2017 / Exhibition place Fira de Barcelona, Barcelona, Spain / On site RoboticsA project in collaboration between IaaC and Tecnalia. / IAAC team (Concept, Coordination, Design, Extrusion, Material & Sensors)Areti Markopoulou, Aldo Sollazzo, Alexandre Dubor, Edouard Cabay, Raimund Krenmueller, Ji Won Junm, Tanuj Thomasm, Kunal Chadha, Sofoklis Giannakopoulos / Tecnalia Team (Cable Robot) / Technology CoGiro / TECNALIA Cable Robotics team:Mariola Rodríguez, Jean-Baptiste Izard, Pierre-Elie Herve, Valérie Auffray, David Culla, Jose Gorrotxategi / TECNALIA Construction Division team:Mikel Barrado, Idurre Fernandez, Juan José Gaitero, Elena Morales, Iñigo Calderón, Amaia Aramburu

Partners → Noumena Team [Drone development, Data collection]Starsky Lara, Chirag Rangholia, Daniele Ingrassia (Fab Lab Kamp Lintfort), Marco Sanalitro, Eugenio Bettucchi, Andrea Melis, Adrien Rigobello / Video Credits Eugenio Bettucchi (Noumena) / Photo CreditsFederica Ciccone (Noumena), LIRMM (Robot research center), Luciano Carrizza (Technical adviser), Joaquim Melchor, Art Cont (Material expert), Lenze (Automation), Wam (Solid process), NanoSystem (Material nanotechnology), Nicolas Weyrich (Video animation)/ Press 3d print, 3d natives, National magazines and media/ MediaTelevisió 3 – Aldo Sollazzo’s interview

Contacts

HEADQUARTER

C/ de Cristóbal de Moura, 203,

08019 Barcelona, Spain

CONTACTS

P (+34) 937 420 927

E info@noumena.io